Importance of Plumb and Straight Rack Columns

- Steve Freant

- Sep 12, 2025

- 2 min read

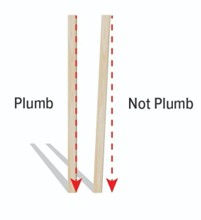

When installing pallet rack, the vertical supports — known as uprights or columns — must be both plumb (perfectly vertical, not leaning) and straight (free from bowing). Plumbness describes how close the frame is to true vertical once installed, while bowed refers to a bend or curve along the length of the column.

If columns lean (out-of-plumb) or bow (out-of-straight) beyond allowable limits, their load capacity decreases. This not only compromises the rack’s structural integrity but also increases the risk of a dangerous collapse.

Operational Challenges of Misaligned Columns

Leaning or bowed columns create more than just safety hazards. They can also make racks harder to use. Safe loading and unloading require the aisle width at the top of the rack to match the clearance at the bottom. For example, if a forklift operator lifts a load to a storage position 35 feet up. They first stage the load six inches from the rack face on the floor, then raise it. If the rack is leaning, or out of plumb, into the aisle, that six-inch clearance shrinks as the load rises — increasing the chance of an unplanned load interaction with the rack.

The tolerances become even tighter in facilities using automated shuttles, cranes, AGVs, or AMRs. Since these systems rely on highly precise navigation, any misalignment can cause errors or damage.

How Engineers Account for Real-World Variations

Even slight out-of-plumb conditions change the way a rack carries loads. Instead of bearing weight purely vertically, the column must also resist side loads. These minor variances often stem from uneven concrete floors, fabrication tolerances, or installation imperfections.

To address this, engineers apply notional loads in their design calculations.

RMI’s ANSI MH16.1 standard specifies strict limits: uprights may not exceed a 1/240 ratio (one inch out of vertical for every 20 feet of height). Any column leaning or bowing beyond this

limit should be immediately unloaded, straightened, and — if damaged — repaired or replaced.

Exceptions to the 1/240 Rule

The International Building Code (IBC) permits installations outside this tolerance if the rack system was engineered for the expected lean.

For example, if a large concrete slab is poured with a uniform thickness over sloped ground, trying to level the rack would require thousands of shims under the base plates. Instead, it may be more practical to engineer the frames to follow the slope.

The Latest in Rack Stability Design

The 2023 edition of ANSI MH16.1 introduces the Direct Analysis Method (DAM) for seismic design. This advanced methodology incorporates notional loads into stability calculations, offering a more accurate picture of how racks respond to seismic forces.

For operations in seismic zones or facilities seeking maximum structural assurance, DAM represents a significant step forward. Please reach out to the team at DIS or EFS to discuss your project needs.

Comments